CLC Blocks (Cellular Light Weight Concrete Blocks) are made of Cellular Light weight concrete (CLC) or Foam Concrete Compared to “classical” procedures, substantial savings in incurred costs is an advantage on the side of lightweight concrete achieving mechanical and physical characteristics according to the purpose and place of use. The savings are achieved first of all by substantial reduction of the labor cost – lower number of workers and substantially shorter construction time.

Foam Concrete

Foam concrete – a lightweight concrete type – it has been known for more than thirty years in its principle. It is a building material with good mechanical strength, low thermal conductivity, simple but highly technological processing directly in the site. Foam concrete contains confined air pockets thus reducing its weight substantially and achieving savings in material inputs. As a building material, it meets all expectations to spread in a building practice first of all in the area of making floors of civic and industrial buildings. Variability of possible characteristics and a wet process in production offer a wide range of applications of foam concrete as a floor levelling layer and a filler of various dead spaces

CLC - Main Fields Of Application

Foam concrete is mainly designed for making filling and levelling layers of floors in civic and industrial buildings, While daily performance of as much as 1000 m² at material thickness of 3-15 cm can be achieved. This high labor productivity, together with optimizing thickness (levelling unevenness) of the bearing layer, bring substantial floor price reduction in comparison with floors made using common levelling materials. Due to self-levelling processing it is an ideal surface for further floor layers.

CLC Block Uses Area

- Subways

- Construction

- Exterior walls

- low cost of living

- High rise Building

- Air-conditioned buildings

- Roof insulation & waterproofing

- Additional floors to existing structure

Main Composition Of CLC Blocks

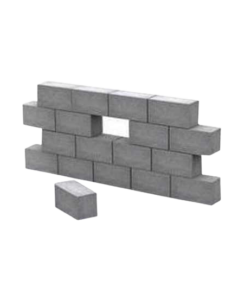

Standard Size of CLC Blocks

- Water

- White Sand

- Foaming Agent

- Portland Cement

- 600mm x 200mm x 100mm

- 600mm x 200mm x 110mm

- 600mm x 200mm x 120mm